Tel:+86-371-67447999

Fax:+86-371-67447888

E-mail:enquiry@lanphan.com

Add:NO.68 Mengjin Road, Shangjie District, Zhengzhou City, Henan Province, China

1.Market or product application :

Vacuum and high-vacuum technology

2. Since 1988, Top 3 manufacturer of stainless steel expansion joint in China;

3.The Main Drafting Committee of National Standard for Expansion Joint;

4. Qualified Supplier for Nuclear Power Plant;

5. ISO9001:2008 and ISO14001:2004 Certified.

Metal bellows, also known as expansion bellows,, bellows expansion joint, is the compensating element for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rods that depend on the application. They are differentiated according to the three basic types of movement: axial, angular and lateral expansion joints.

Stainless Steel Expansion Joint is elastic vessel that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape (provided the material has not been stressed past its yield strength).

Features:

Economical end usage

Providing for lower initial costs in piping & construction work

Applications:

Diesel engine sets

Pipelines

Turbines

Compressors

Blowers

Vacuum pumps

Heat exchangers

Advantages:

Reduce vibration

Dampen sound transmission

Compensate lateral, torsional & angular movements

Compensate axial movements

Minimal face-to-face dimensions

Lightweight

Low movement forces required

Reduced fatigue factor

Reduced heat loss

Corrosion, erosion resistant

No gaskets

Lanphan Stainless Steel Expansion Joint:

Why us:

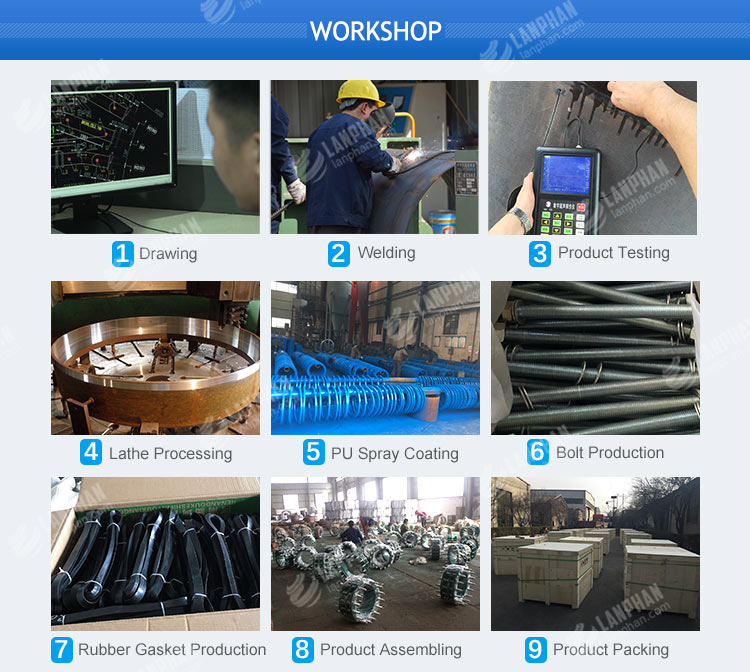

Henan Lanphan Industry Co.,Ltd. is a leading manufacturer of stainless steel expansion joint in China. We have:

(1) Strong R&D strength;

(2) Strict Quality Control System;

(3) Perfect Test System;

(4) Professional After-sale Service Team;

(5) OEM Service.

We are your qualified supplier and reliable friends!

| nominal diameter DN | length L | axial displacement | horizontal displacement mm | deflexion angle a1+a2 | ||

| mm | inch | extension mm | compression mm | |||

| 32 | 1 1/4 | 95 | 6 | 9 | 9 | 15 |

| 40 | 1 1/2 | 95 | 6 | 10 | 9 | 15 |

| 50 | 2 | 105 | 7 | 10 | 10 | 15 |

| 65 | 2 1/2 | 115 | 7 | 13 | 11 | 15 |

| 80 | 3 | 135 | 8 | 15 | 12 | 15 |

| 100 | 4 | 150 | 10 | 19 | 13 | 15 |

| 125 | 5 | 165 | 12 | 19 | 13 | 15 |

| 150 | 6 | 180 | 12 | 20 | 14 | 15 |

| 200 | 8 | 210 | 16 | 25 | 22 | 15 |

| 250 | 10 | 230 | 16 | 25 | 22 | 15 |

| 300 | 12 | 245 | 16 | 25 | 22 | 15 |

| 350 | 14 | 255 | 16 | 25 | 22 | 15 |

| 400 | 16 | 255 | 16 | 25 | 22 | 15 |

| 450 | 18 | 255 | 16 | 25 | 22 | 15 |

| 500 | 20 | 255 | 16 | 25 | 22 | 15 |

| 600 | 24 | 260 | 16 | 25 | 22 | 15 |

| 700 | 28 | 320 | 16 | 25 | 22 | 15 |

| 800 | 32 | 340 | 16 | 25 | 22 | 15 |

| 900 | 36 | 370 | 16 | 25 | 22 | 15 |

| 1000 | 40 | 400 | 18 | 26 | 24 | 15 |

| 1200 | 48 | 420 | 18 | 26 | 24 |

15 |